Recent Posts

- The Evolution of Slot Technology: From Mechanical to Digital

- The Science of Slot Machine Symbols: How Icons Influence Gameplay

- Life Insurance for Pharmacists: Protecting Earnings and Career Potential

- Healthy Home Pest Control: Implementing Integrated Pest Management Strategies

- Betting Fundamentals: Mastering the Fundamentals of Betting Theory and Practice

Recent Comments

bola16 LOGIN MENARA4D Local Viking range repair koitoto MENARA 4D rupiahtoto Bola16 Slot Gacor toto spin login pgsoft 10rb Bandar togel PAP4D padangtoto ingatbola88 Pussy888 Download rungkad bandar togel mahjong118 zeus slot slot zeus zeus slot Sabung Ayam Online liveslot365 liveslot365 mahjong ways 2 https://dewansengketa.id/wp-content/upgrade/app/config/ akun pro thailand اسم سایت های شرط بندیสล็อตเว็บตรง

bagnall haus price MOLE4D KENANGAN4D SV388 MPO Slot sv388 autospin777 rtp live tradisibet the arcady at boon keng showflat MEGA888 bio88 slot situs mpo slot Servertogel Servertogel Slot Thailand slot thailand onic77 login slot thailand MOLE4D KENANGAN4D padangtoto BBNI4D rupiahtoto Jeparatoto padangtoto https://ekobintang.com/ totobet 22 BBTN4D hotel4d musik4d Topcer88 Topcer88 kenangan4d Cactus Labs iramatogel login PEWE4D BBNI4D Link Kingcobratoto Mailhosting slot online KKSLOT777 login dana69 Dana69 Angkanet slot Axa Claims Number sakura slot slot88 server thailand Kera4d slot gacor Auto Lautsprecher Systeme Slot link slot thailand livetotobet slot gacor hari ini bandungtoto slot server https://espacioiaunesco.org/ slot88 resmi Raja Slot link slot gacor situs online gacor GTA138 situs toto real estate franchise weichert Sultan88 Betwin188 slot88 deposit pulsa indosat 10rb pohon4d Crypto Trade Mastermind slot88 deposit pulsa tri 10rb slot gacor online nexus slot online

master togel car insurance online situs togel pokkawin situs togel bet 100 ug808 agen togel situs togel togelup bo togel slot gacor 88 kebaya4d situs togel Slot server Thailand Duta168 Slot Online Slot gacor https://www.infoselebriti.top https://www.selebterkini.live/ Doubledown Forum Yuk69 Koitoto168 slot dana topjitu login Server Thailand winslot slot gacor slot gacor Grinding Gear games blaze entrar

online cricket betting site slot gacor hari ini marketing1on1 pohon4d

เว็บสล็อตใหม่ล่าสุด keputusan GD Slot Gacor Hari Ini djarumtoto slot taktik88

weight loss steroids for sale 3milyartoto Djarumtoto slot demo pg http://www.tint21.com 3a娛樂城 haka4d mugiwaraslot

Slot Thailand 777

slot gacor hari ini

Slot Online

UGFREAK gta online

slot gacor

Slot Gacor

Djarumtoto slot gacor situs slot gacor Login Indobet

Superdrol for sale weight loss steroids for sale uk presidenttoto

situs slot

สล็อต

เว็บตรง

สล็อต

หวย

สล็อต

SLOT GACOR 4D

link slot gacor/ sultantoto situs slot thatslikewhoa jadwal slot toto slot INFINI88 mastertoto

situs toto slot

situs toto

INFINI88

สล็อต

สล็อต

娛樂城 SBOBET88 rtp slot88 judi bola slot nexus engine WIN88 SLOT88 ULTI234 situs slot terpercaya Slot Gacor slot gacor minimal deposit 5rb apidewa

สล็อต pg เว็บตรง แตกหนัก

เว็บสล็อต slot gacor judi slot 3milyartoto

線上真人娛樂

สล็อตเว็บตรงฝาก-ถอน true wallet ไม่มีขั้นต่ํา slot888 vip cambodia Daftar Indobet lapak303 situs judi sabung ayam online sv388

娛樂城推薦

สมัครสมาชิก สล็อตเว็บตรง

เว็บตรงสล็อต papuatoto สล็อต

娛樂城推薦

เว็บตรง

dewapoker poker88 https://pohon4d.site/ dewapoker poker88 slot pragmatic

Agentoto

slot gacor gratis maxwin88 zeus138 Rajacuan Gacor77

toto88

manadototo Slot depo gopay Data macau laris99

indobetpoker

Data macau

demo slot pragmatic

koin55

Data macau

togel online

auto7slot slot thailand daftar auto7slot agen sbobet judi online

Slot88 Terpercaya

sarana99 online138 Metrowin88 Kostenloser Porno

Slot Online Slot bonus new member https://decalstor.com/

merahtoto

talent management slot https://zerotrollerance.guru/ Demo slot metrowin88 Live Draw California sexy lingerie 訂花 slot online game slot online situs slot terbaru Situs slot gacor hari ini Slot Taiwan Slot Shopeepay BENTO 4D roulette casino slot gacor hari ini del-immune birutoto tungsten wedding bands rajacuan slot 먹튀폴리스 Freebet สล็อต rtp slot slot demo demo pg soft AKUN DEMO SLOT flavorz disposables buy targeted traffic https://mtpolizia.com/ 사나이 회원가입 https://dewatogel88.life/ matka slot88 Shibatoto Daman Games daman games Slot Demo unblocked games world カラコン Daman games login HealthPlanTotal slot online ZLD SYSTEM MANUFACTURER jdclub9.co/sg/en/evo888

777slot

slot777

slot gacor malam ini

slot pragmatic play

Cryptocurrency Systems and Software Optimum Blinds

Slot Online

http://nheri.re.kr/ jasa aspal murah LumBuy

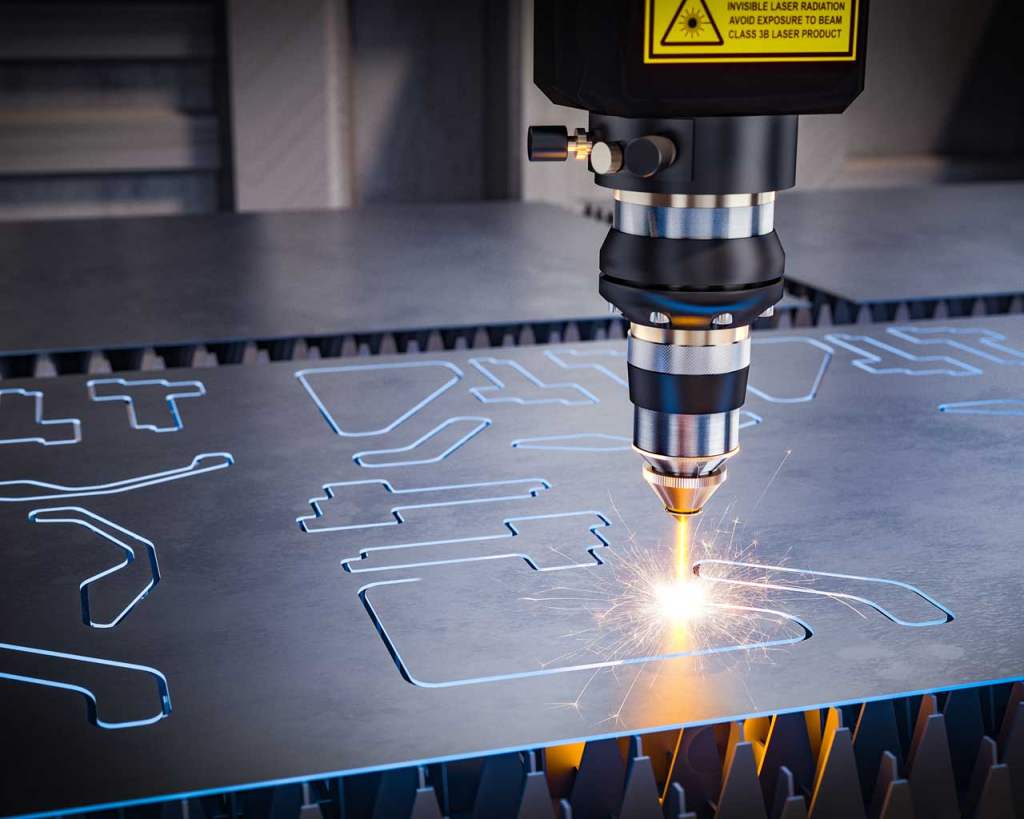

Laser chopping companies have appeared as the top of precision in the world of fabrication and design. Utilizing the energy of aimed supports of light, laser cutting is really a technological miracle that brings unmatched accuracy and usefulness to many industries. In that exploration, we search to the complex world of laser cutting solutions, understanding their programs, advantages, and the transformative affect they’ve on the realms of manufacturing, style, and beyond.

At the key of laser cutting lies the ability to achieve reductions of extraordinary precision, enabling the formation of elaborate styles and complicated habits that have been when tough to accomplish through traditional chopping methods. The laser beam’s concentrated depth enables little substance wastage, ensuring performance and cost-effectiveness in creation processes. That accuracy extends to a varied range of materials, including metals, materials, timber, textiles, and more, making laser cutting a adaptable option for numerous industries.

The advantages of laser cutting are manifold, particularly in manufacturing. The process enables the quick prototyping of styles, facilitating fast iterations and adjustments. This agility is priceless in industries wherever time-to-market is just a critical factor. Furthermore, laser cutting provides for the production of extremely step-by-step components with smooth ends, causing the entire quality and operation of the conclusion product. From automotive elements to intricate digital components, laser cutting is becoming fundamental in the production landscape.

Among the standout features of laser chopping services is the ability to make use of a varied selection of materials. Laser blades can simply slice through materials, giving precision in purposes like sheet material manufacture and complicated steel artwork. Concurrently, the exact same laser cutter may softly etch intricate habits on fine components such as paper or cloth, showcasing the usefulness that sets laser cutting besides standard chopping methods.

The impact of laser cutting extends beyond production to the realms of design and creativity. Musicians and designers control laser chopping solutions to breathe living into their dreams, producing comprehensive statues, architectural designs, and bespoke pieces that drive the boundaries of what’s achievable. The finesse with which laser blades handle materials enables the recognition of delicate habits, personalized engravings, and three-dimensional patterns, opening up new opportunities for innovative expression.

In addition to precision, laser chopping solutions offer performance and speed. The non-contact nature of the method eliminates the necessity for bodily software changes, lowering downtime and permitting continuous and uninterrupted cutting. That efficiency is particularly essential in large-scale manufacturing, where rapid turnaround occasions are necessary for conference market demands.

The introduction of laser cutting in addition has ushered in a brand new era of customization and personalization. Whether it’s developing intricate styles on wedding invitations or making special signage for organizations, laser chopping companies inspire persons and businesses equally to impress a touch of personalization to their projects. The technology permits the Steel plate suppliers South Africa of complex and step-by-step patterns with uniformity and repeatability, ensuring that each and every item is a work of accuracy and artistry.

In summary, laser chopping services symbolize a top of precision, flexibility, and effectiveness in the realms of production and design. From the formation of intricate parts in industrial options to the conclusion of artistic ideas in innovative spots, laser chopping is becoming an vital tool. The marriage of technological complexity and creative freedom makes laser chopping services a major power, unlocking new opportunities and placing new criteria of precision in the world of manufacture and design.